|

|

|

|

|

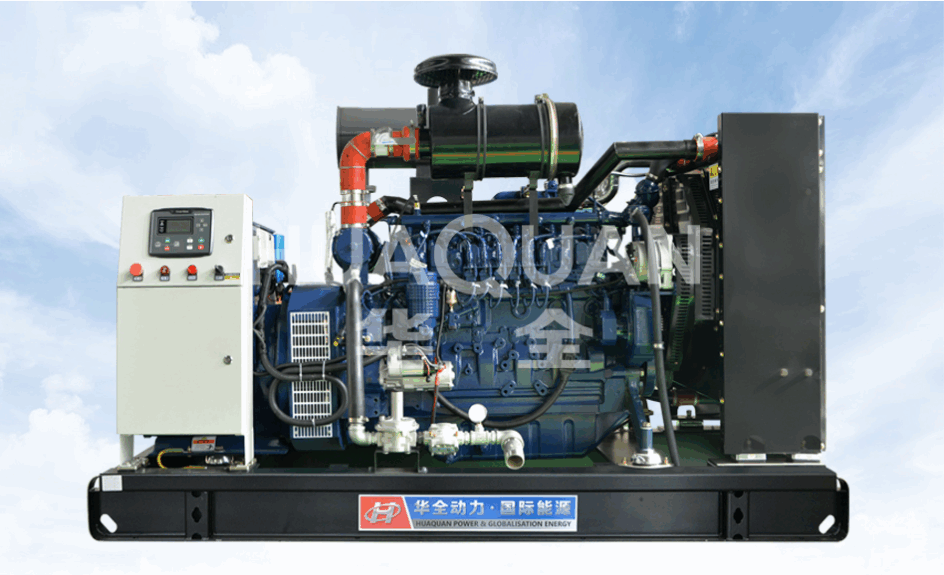

| 1. The design standard of the biogas unit is 100kW/125kVA, the voltage is 400V, the working frequency is 50Hz, and the power factor is 0.8 (lagging). The biogas engine can work in different methane gas concentration ranges (50-97%) or gas with the same calorific value, producing 100% electricity. |

|

| |

|

|

| 2. For the generator set running at normal operating temperature, the voltage, frequency change rate and engine recovery time conform to the ISO8528-5 standard, that is, to meet the 25% stepwise sudden load at the beginning, from the 25%-60% load stage Suddenly add 15% of the rated load, add 10% of the rated load from the 60%-80% load stage, and withstand 25% of the sudden load drop. |

|

| Gas requirements: |

| Fuel type |

Biogas |

| Intake pressure |

8Kpa-15Kpa, pressure change rate ≤1Kpa/min |

| Methane content |

≥55% |

| Low calorific value (LHV) |

≥25MJ/Nm3 |

| Impurity particle size |

≤5μm, content ≤30mg/nm³ |

| Sulfide |

≤50mg/Nm3 |

| Intake air temperature |

≤40℃ |

| Moisture content |

≤40g/nm3 |

|

Note: Demineralized water should be used for the high and low temperature cycles of the engine, and the cooling water should be slightly alkaline clean water, and must not contain corrosive compounds such as chloride, sulfate or acid. The main index requirements are as follows:

|

| Hardness 0.7~5.3me/L |

| Chloride ion content <150mg/L |

| PH value7~8.5 |

|

|

|

|

|

|

|

|

|

|

| █The generator is a synchronous generator, four-outlet, closed connection type, and the shrapnel is directly driven. The generator is equipped with a brushless rotating magnetic field. |

| █The generator should be closed and installed on the engine and the main rotor should be installed on the engine flywheel, using a flexible drive disc to ensure permanent alignment. |

| █The generator is an open waterproof drip design and is equipped with a protective device, manufactured according to IEE, NEMA MG-1-22 and IP23 standards, single bearing, raised electrode, rotating magnetic field, synchronous damping winding coil and 2/3 pitch The stator coil produces the most ideal voltage waveform. |

| █Protection level of forming winding and coastal climate, using vacuum pressure dipping process. The stator coil should be 2/3 pitch. The rotor and stator coils should be fully reinforced to withstand phase-to-phase and ground-to-phase failures. |

| █All insulation systems should be Class H of NEMA MG-1 standard. The stator has two dipping and drying (according to Class H insulation requirements). |

|

|

| It is a solid-state electronic type, voltage/Hz type, three-phase voltage sensing to maintain the voltage within the following range: |

| █Steady-state voltage regulation: ±0.5%, under any constant load (from zero load to full load). |

| █Voltage adjustment rate: ±5.0% in the no-load state, the maximum and minimum voltage adjustment rate. |

| █Filtering: The telephone influence factor is less than 50. |

| █When over-excitation exceeds ten seconds, the voltage regulator should have over-excitation protection to turn off the generator output. |

| █The voltage regulator has KVAR/PF control and runs in parallel with the grid. |

|

| Noise and vibration |

| Each gas generator set is equipped with an exhaust muffler designed and manufactured by self-processing to minimize the exhaust noise of the gas generator set. Principle dynamic design, lower temperature. Between the biogas engine, the brushless generator and the base of the generator set, and between the unit and the chassis, a shock absorber with shock absorption function is configured to minimize the vibration generated by the operation of the unit. |

| Exhaust emissions (purchase separately according to local environmental protection) |

| At the exhaust outlet of the biogas generator set, a tail gas purification system is configured to ensure that the tail gas meets the emission standards. |

| Wastewater and others |

| During the operation of the unit, no waste water is discharged; the replaced old lubricating oil is treated centrally and will not cause pollution. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

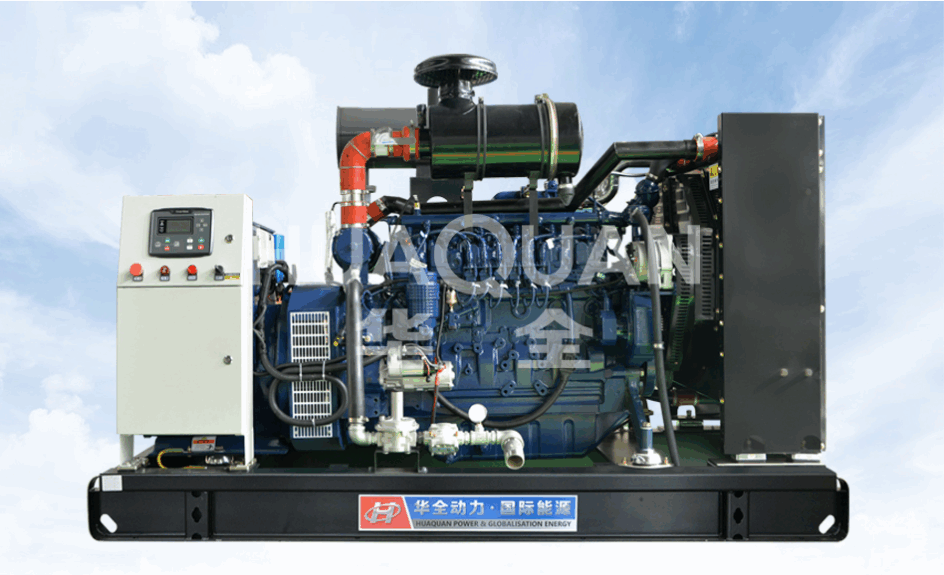

| Strong gas adaptability |

NG, LPG, biogas, syngas, gas |

| Strong flexibility |

The control function and interface are perfect, which can easily achieve the balance of project requirements |

| Durability |

All fuel valves are designed to be resistant to corrosive gases, with high durability and reliability.The strategy has a correction function, and the emission durability is good |

| Transient response capability |

High-speed motor-controlled gas control device with fast transient response capability.Optimized boost pressure control, while taking into account the stability while responding quickly.The system can be adapted to the main power electric drilling rig in the oil field.The system can be adapted to the main power mechanical drilling rig in the oil field

|

| Engineering supporting capacity |

Matching experience of control system and engine Can be developed according to customer's special needs |

|

|

|